- MAAG /

- Gears

Gears

Powering your productivity with our gears

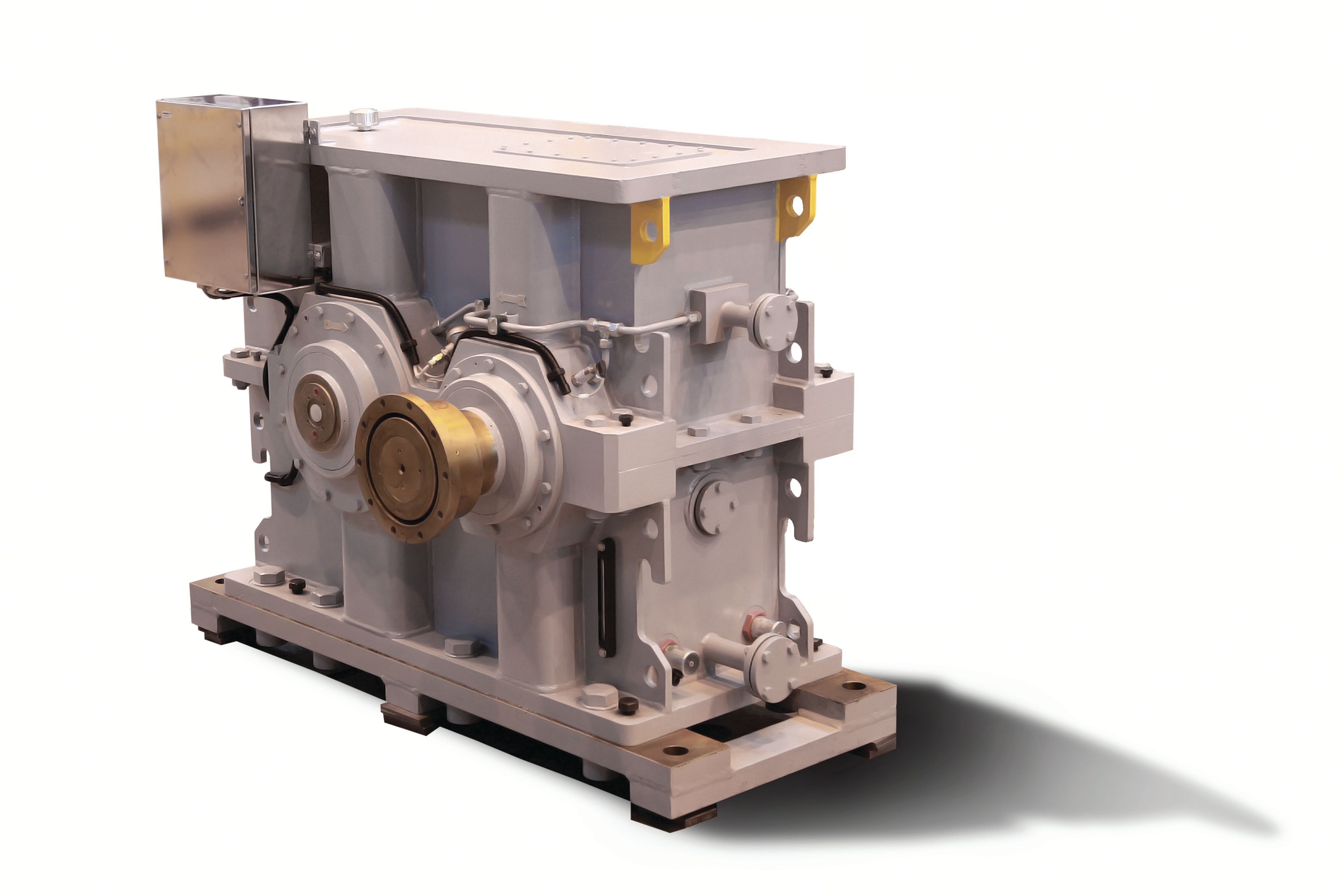

MAAG® GEARS

The reliability and efficiency of your gear units and drive systems can make or break your process. With more than 100 years of experience behind our design and technologies, we deliver durable, efficient gear units for heavy duty applications supported by process expertise and smart maintenance solutions.

V K Jain

CTO, Jaiprakash Associates LTD

Ayed Al-Fayedi

Maintenance Manager, Arabian Cement

- Gears for Vertical Mills

- Gears for Ball Mills

- Gears for SAG Mills

- Gears for Rolling Mills

- Gears for Excavators

- Gears for Conveyors

- Gears for Crushers

- Gears for Sizers

- Gears for Dryers

- Gears for Roller Presses

- Gears for Presses & Steel Presses

- Gear Pumps and Extruders

- Replacement Kits

- Kilns

- Equipment life-cycle management

Gears by category

Browse our product portfolio by category

All gears

Gears for vertical roller mills

Our comprehensive line of gear for vertical roller mills excels in many applications, including coal or raw material comminution and cement grinding. With power output ranging from a few 100kW to over 10MW, we have the drive solutions and gear units to meet your needs – and optimise your production.

Gears for roller presses

Highly standardised without sacrificing flexibility, our MAAG® GEAR gear units provide smooth, durable operation for your roller presses. Our comprehensive range of auxiliary equipment further extends the scope of our planetary gear units – and delivers exactly what you need for your cement and raw material grinding.

Gears for other applications

The high-quality and modular nature of our MAAG® KA and KB gear units for conveyors mean they are sure to meet your precise industrial gear requirements in the cement and mining industries.

Gears for horizontal mills

Our gear units work efficiently and reliably with the various types of horizontal mills in the cement and mining industries. We provide both central and lateral drive systems that use multistage spur gears, planetary arrangement or simple girth gear pinion drives – whatever best suits your requirements.

Gears for crushers

Our long experience with heavy-duty gear units gives us the expertise to design and produce top-notch bevel sets for crushers in the cement and mining industries. This know-how translates to high-quality, dependable geared components with low maintenance requirements – bringing high-performance to your crushers.

Gears for kilns

Get in touch with our experts to discuss your specific demands.

News

ALL ARTICLES

Sunday, 23.11.2025

Join our newsletter.

Don’t miss out on the latest news, updates,

and insights - from MAAG.

© copyright MAAG Gear 2025. All rights reserved.

MAAG GEAR

INDUSTRIES

SERVICE CENTER

INDUSTRIES

SERVICE CENTER